Airflow Sensor / Mass Air Flow Sensor

MAFFuel-injected engines use an airflow sensor to measure how much air is being drawn into the engine. The sensor sends that data to the Engine Control Unit (ECU), which calculates how much fuel is needed to maintain the correct air/fuel ratio. The two main approaches are Mass Air Flow (MAF) sensors — which measure the actual mass of incoming air — and Manifold Absolute Pressure (MAP) sensors, which infer airflow from intake manifold vacuum. MAF sensors come in several designs: Hot Wire MAF uses a heated platinum or tungsten wire that cools as air flows past it, and the ECU measures the current needed to maintain constant temperature. Hot Film MAF operates on the same principle but uses a more durable flat thin-film resistor element instead of a wire. Vane Air Flow (VAF) is an older volumetric design where incoming air pushes a physical flap connected to a potentiometer. Kármán Vortex is a more advanced volumetric design that detects swirling air patterns using optical sensors, with vortex frequency proportional to air velocity.

Hot Wire MAF — the most common type. A heated wire cools as air flows past; the ECU measures current needed to maintain temperature.

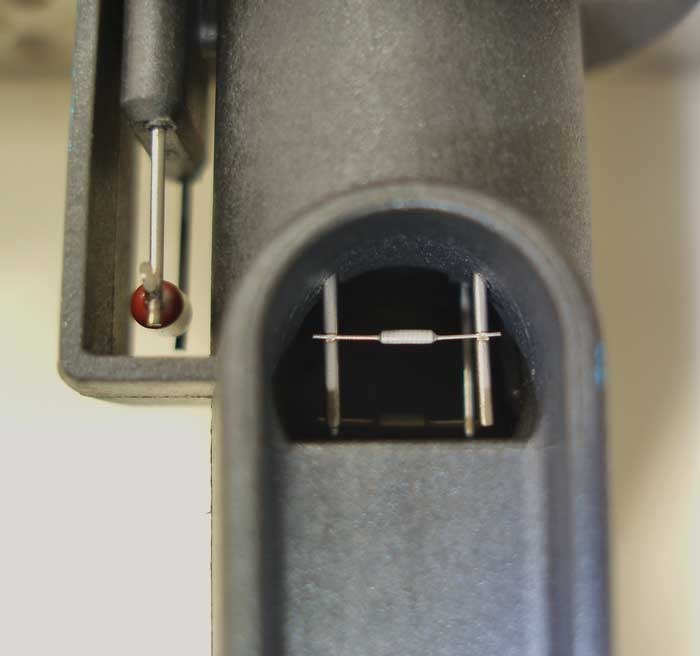

Hot Wire MAF internals: heated platinum/tungsten wire (center) and intake air temperature sensor (left). These two elements work together for accurate mass air measurement.

Hot Film MAF — uses a durable thin-film resistor instead of a wire. Same principle, greater longevity. Widely used in modern European and Asian vehicles.

Vane Air Flow (VAF) — an older volumetric design. Incoming air pushes a physical flap; a potentiometer measures position. Common on 1980s–1990s vehicles.

Kármán Vortex — detects swirling air patterns via optical sensors. The mesh screen conditions airflow for accurate vortex frequency measurement.